Water Plants

Leading Manufacturers, Exporters, Wholesaler and Retailer of Automatic Demineralization Plant, Digital Conductivity Meter, Digital Ph Meter, Dm Water Plant, Effluent Treatment Plant, Electrodeionization Plant, Industrial DM Water Plant, Mini Demineralization Plant, Mix Bed Plant, Reverse Osmosis Plant, Swimming Pool Filtration Plant, Ultrafiltration Plant, Water Softener Plant, water softening plant and Water Treatment Plant from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Industrial |

| Certification | CE Certified |

| Warranty | 1 Year |

| Country of Origin | India |

Pure water is most essential to live a healthy life but in today’s polluted environment, it has become increasingly difficult. There is a serious need for an advanced purification system, one that is able to remove excess dirt, contaminants from water and bring it out as clean, fresh so that it can be consumed for commercial or industrial purposes. One such system is the Aqua Systems Technology DM Plant, which removes minerals and solid contaminants from the water, making it clean and pure for use.

How Does A DM Plant Operate?

In a DM plant, the purification process is carried out on water such that dissolved solids and minerals are removed and clean water is obtained. Source of water for the system is a water feed, which comes inside the plant and is subject to procedures such as distillation, deionization, electro dialysis and membrane filtration. It also works to prevent scale formation and meal oxidation in the water. It is available in different sizes and materials and you can find units that are either manually operated or completely automated. It can be purchased as a standard else a custom built model for carrying out purifications according to specified needs.

The process by which the Aqua Systems Technology DM plant makes water pure is through demineralization, which involves removing minerals salts present in water through an ion-exchange process. Here is a look at the process occurring inside a DM Plant:

- Step 1 - Raw water is sent into the cation resins column

- Step 2 - Cation resins column converts the ionized salts in raw water into appropriate mineral acids

- Step 3 - Raw water with the mineral acids is sent into Anion Resins Column where it is absorbed

- Step 4- De-mineralized (Deionized) water comes out from the Anion Resins Column

When cations Resins become exhausted they are rejuvenated using Hydrochloric acid and likewise occur with Anion resins using caustic Soda (NaOH) solution. Hence resins present in the plant can be used over and over again. The prime means by which the DM plant removes contaminants and minerals from water that is fed into it is through the ion exchange method. However the level of purity of this water is determined by the DM Plant type.

The latest Aqua Systems Technology DM plant is easy-to-operate, user-friendly, uses less power and is robust in quality so it can be used for long periods to do water purification. In the plant’s single body unit is present strongly acidic cation and anion exchange resins, which carry out the demineralization process. This process removes hardness from the water, making it soft.

Use of a DM Plant is most suitable for industries such as pharmaceutical, food, electroplating etc. when there is a need to feed clean water into a boiler system. In the pharmaceuticals and cosmetics DM water is used in the preparation of products to ensure that they have quality and safety. It is used in many inductors for the purpose of sanitizing containers and also equipment.

We are one of the prominent manufacturers of premium-quality DM Plant. DM plant consists of cation and anion beds. Raw water is passed through the cation bed, which converts all ionized salts to the equivalent mineral acids. The anion bed then absorbs these acids to finally give de mineralized and deionized water. When resins are exhausted, the cation resins are re-generated with Hydrochloric acid and the anion resins are regenerated using caustic soda. We supply DM plants to clients at affordable prices.

Features :

- Easy to install

- Easy to maintain

- Affordable

DM plant consists of two Beds (Cation & Anion) Water Quality (Conductivity) from Two Bed Outlet will be between 15 to 20 micro siemens. First raw water is passed through the cation resins column (H+ form), which converts all ionized salts to the equivalent mineral acids. Then Anion Resins Column (OH form), which absorbs these acids and finally gives De mineralized (Deionized) water. When resins are exhausted - the cations Resins are regenerated with Hydrochloric acid (Hcl) and the Anion resins are regenerated by caustic Soda (NaOH) solution. So the same resins can be used over and over again to produce the DM water.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Country of Origin | India |

| Warranty | 1Year |

| Frequency | 50Hz-65Hz |

| Weight | 200-300gm |

| Type | Digital Conductivity Meter |

| Display Type | Digital |

| Voltage | 230 V AC |

| Feature | Accuracy |

| Certification | CE Certified |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Color | Red, BLACK |

| Material | Plastic |

| Port | COURIER |

| Delivery Time | 1 week |

Online digital conductivity meter

| Business Type | Exporter, Supplier |

| Display | DIGITAL |

| Country of Origin | India |

| Warranty | 1Year |

| Frequency | 50Hz-65Hz |

| Weight | 400-500g |

| Type | Digital Ph Meters |

| Display Type | Digital |

| Voltage | 230 |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Indsustrial Usage |

| Power Source | Electric |

| Automatic Grade | Automatic, Fully Automatic, Manual |

| Color | Red, BLACK |

| Body Material | Plastic |

| Brand Name | ASTER |

| Product Code | PH METER |

| Port | COURIER |

| Payment Terms | Other |

| Delivery Time | 1 WEEK |

| Packaging Details | Courier |

DIGITAL PH METER

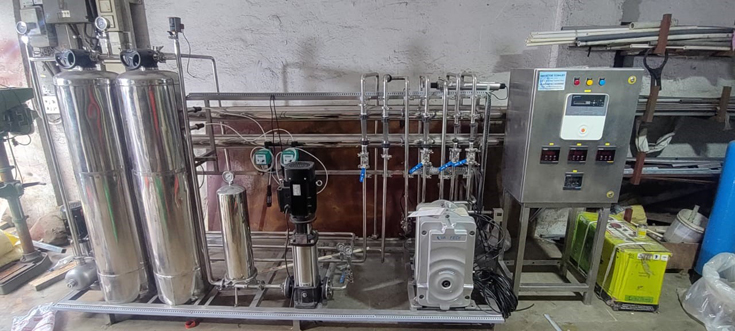

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | AST |

| Material | FRP |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Manual, Semi Automatic |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 110V, 220V |

| Type | Dm Water Plant |

| Weight | 100-1000kg |

| Country of Origin | India |

| Payment Terms | Other |

| Packaging Details | INSTALLED PLANT |

DM WATER PLANT / MINI DM

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Driven Type | Electric |

| Application | Industrial |

| Certification | CE Certified |

| Warranty | 1 Year |

| Country of Origin | India |

An Effluent Treatment Plant (ETP) is a process for treating waste water in textile, chemical, and pharmaceutical industries, where the water is contaminated to an extreme. Some of the many pollutants that can be treated by it include organic and inorganic matter, oil, grease, heavy metals, suspended particles, and much more. By using it, fresh water is not unnecessarily used for production purposes or commercial activities. It is an effective way to prevent water pollution.

At various levels, the plant carries out different processes such as physical, chemical, membrane, and biological so that the waste water is effectively treated and the water coming out is pure and safe for consumption.

Water that comes into the Aqua Systems Technology effluent treatment plant can be from sources like reservoirs, lakes, rivers, and outlet pipes, in addition to industries and factories. By cleaning up the effluent water, it puts it back into circulation where it can be utilised for a different purpose. Examples of some industries that make use of it include those that manufacture medicine, leather, textiles, and chemicals. In such industries, the use of this plant helps them to follow government regulations on pollution emission and also prevents them from spending unnecessary money on acquiring water for various activities.

A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.

Aqua Systems Technology is one of the best Effluent Treatment Plan manufacturer, Effluent Treatment Plan exporter, Effluent Treatment Plan supplier in mumbai India. We are provide this Effluent Treatment Plan product in all over countries. If you have this Effluent Treatment Plan product please visit here or quote Now.

We are engaged in manufacturing premium-quality Effluent Treatment Plant (ETP). Manufactured using corrosion-resistant Mild Steel and CPVC, they are the most cost-effective and technically proven systems to remove the unwanted, hazardous chemicals from waste-water to meet the statutory pollution control requirements. Such plants are especially required for chemicals, pharmaceuticals, phosphate and electroplating waste waters. We undertake turnkey projects of various capacities as per the client's requirements.

Effluent Treatment Plant (ETP) is most cost Effective & technically proven system to remove the unwanted, hazardous chemicals from the waste water to meets the statutory pollution control requirements, especially for chemicals, pharmaceuticals, phosphate and electroplating waste waters. We undertake turnkey project of various capacities as per the client's requirement.

Salient Features :

- Very cost effective: Less initial investment.

- Compact and proven design: required very minimum area for mounting.

- Quality products and piping items: special sludge pump and total corrosion free Cpvc piping & FRP/Epoxy coated MS tanks.

- Water recycle: You can recycle treated water to some of your process applications

- Easy Operation and maintenance: Plant is easy in operation and any unskilled person can operate it, after proper training.

- Flexible design: Starting from 500 Lit/day to 50,000 Lit/day capacities

- Recurring Expenses: Economical plant operating cost.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

Electrodeionization (EDI) is used after reverse osmosis for polishing of demineralized water to obtain low levels of conductivity and silica. The EDI uses ion exchange membranes, ion exchange resins and electricity to produce high-quality water with no regeneration downtime. EDI is an alternative to a conventional mixed bed polisher. Electrodeionization System (RO EDI Plant) technique can achiever high purity of Deionized water with conductivity less than 0.1 μS/cm.

EDI advantages

- CONTINUOUS PROCESS : EDI provides a simple and continuous operation with no downtime due to the electrochemical regeneration.

- NO USE OF CHEMICALS : EDI utilizes chemical-free regeneration. Therefore, no storage or application of chemicals is required.

- SPACE-SAVING PLANTS : The EDI plants are space-saving due to the very compact design.

Typical Applications of EDI

- Water for power plant : Instead of using a conventional mixed bed, a membrane degasser in combination with EDI can produce high-quality demineralized water without using any chemicals. This provides corrosion-free boiler feedwater with low conductivity and silica content.

- Ultrapure process water : EDI after reverse osmosis supplies ultrapure process water with low conductivity. The photo shows EDI for ultrapure water at a microelectronic company. The EDI is customized with special pharma modules for a hygienic design.

- Water for pharma : Purified water production within pharma industries requires a water treatment system in a hygienic design. The EDI is customized to meet the current versions of Standards.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Manual, Semi Automatic |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 220V |

| Type | Dm Water Plant |

| Weight | 100-1000kg |

| Country of Origin | India |

| Port | JNPT |

| Payment Terms | Other |

| Delivery Time | 2 weeks |

| Packaging Details | INSTALLED PLANT |

DM WATER PLANT / INDUSTRIAL

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Driven Type | Electric |

| Color | Blue |

| Application | Industrial |

| Certification | CE Certified |

| Warranty | 1 Year |

| Country of Origin | India |

| Port | Transport |

| Payment Terms | Other |

| Packaging Details | Transport |

We are manufacturer of the Mini DM Water Plant. Demineralized water systems are used in the fields of cooling, power, process. Two Small beds filled with ion exchange resins are used to give demineralized water. In the first bed, the cations exchange with hydrogen ions, and in the second, the anions exchange with hydroxyl ions.

The DM plant must have minimum two resin columns, Cation and Anion. The resins in the cation unit are in the H form, while the anion resins are in the OH- form during the service cycle. When the raw water is run through a two-bed DM plant, cation resins exchange all the cations in the water, converting the salts to the appropriate acids. The anion resins are used to exchange the anions as the acidic water is passed through them to produce pure water. TDS levels in the water leaving an anion unit is < 25 ppm.

If someone needs < 1 ppm water TDS then small mix bed can be incorporated with non - rechargeable mix bed resin after Anion bed unit.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Voltage | 220 V |

| Country of Origin | India |

| Frequency | 50/60 Hz |

| Size | Standard |

Mix Bed Plant are ion exchangers that include both cation and anion resins that are put together into a single vessel so that pure water can be created. This plant has a mix of strong acidic and basic cations in the perfect ratio. The kind of water quality that comes from a mixed-bed deionizer is definitely better than what is produced by a two-bed machine. It can also be used to further treat water that has already been cleaned by a R.O plan so that its degree of purity increases.

The strength of the Aqua Systems Technology mix bed plant purification system of a mix bed plant lays in the fact that strong acid cation and anion resins are brought together into a single column. Consequently, a mix bed plant carries out the same function as done by thousands of dual bed plants. Its key quality is that it is a single shell unit with a strong, accurate mixture of acidic and basic cations in a ratio that’s 40% cation resin and 60% SBA resin infused into mixed bed shells. Water passes through the cation and anion exchangers then comes in contact with the mix bed unit, creating high quality water that is sent through an outlet. It is an easy-to-install and affordable water treatment system.

A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.

Aqua Systems Technology is one of the best Mix Bed Plant manufacturer, Mix Bed Plant exporter, Mix Bed Plant supplier in mumbai India. We are provide this Mix Bed Plant product in all over countries. If you have this Mix Bed Plant product please visit here or quote Now

We are engaged in manufacturing premium-quality Mix Bed Plant. They provide water that is even more pure than the water provided by D.M.Plants. Made in compliance with industrial quality standards, mix bed ionizers are single column units, filled with strongly acidic and strongly basic anion exchange resins mixed together. We offer them to clients at affordable prices.

Features :

- Easy to install

- Quality-tested

- Affordable

Further high purity water can be achieved after d.m.plant by Mixed Bed Deionizers, which are designed to produce high purity treated water. They can be used as polishing units after two beds DM Plant to obtain high purity water. Mixed Bed Deionizers are single column units, filled with strongly acidic cation and strongly basic anion exchange resins mixed together. Water Quality (Conductivity) from Mixed Bed Outlet will be less than 1 microsiemens.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Color | Blue, Green |

| Application | Industrial |

| Certification | ISI Certified |

| Voltage | 220V |

| Country of Origin | India |

R.O stands for reverse osmosis process which removes elements ranging from giant particles, bacteria and also unwanted ion from water. It is carried out by an Aqua Systems Technology R.O Plant which is so designed to remove any salt and contaminants from water using a partially permeable membrane so that it can be used for drinking purposes. Through this plant water that has impurities which make it unsafe for consumption can be put back into circulation and used as required. Typically the plant takes in tap water and reduces its hardness and also debris that has been put into it as it travelled through metal pipes.

Inside the plant pressure is applied to the concentrated part of the membrane which pushes clean water into its dilute side that is sent out via an outlet to the connected pipe. The impure water is washed away through the reject water outlet. In industries and factories where production requires a constant source of clean water, installing an R.O plant is essential. It is an economical water treatment solution, one that uses less energy than traditional large scale water treatment systems. Some of the many sectors in which it is used are hospitals, pharmaceuticals, dairy plant, beverage treatment, pretreatment for boilers, industrial wastewater management ad much more.

A team of qualified and experienced TECHNICIAN is always on it's toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.

Aqua Systems Technology is one of the best R.O Plant manufacturer, R.O Plant exporter, R.O Plant supplier in mumbai India. We are provide this R.O Plant product in all over countries. If you have this R.O Plant product please visit here or quote Now

The Aqua Systems Technology desalination unit uses the reverse osmosis process to remove dissolved solids from brackish or saline water. The process is continuous and requires no regeneration chemicals. The unit is factory tested and easy to install and operate. Treated water quality is continuously monitored by a Total dissolved Salt indicator.

Reverse Osmosis System

Exploding population, industrial effluents, and reckless deforestation have depleted natural sources of pure water. Dependence on erratic monsoons to replenish these sources has proved extremely inadequate & expensive. Good management of existing water resources and untapped sources, along with recovery and recycling of Industrial effluents & municipal waste water, seem absolutely essential for the future of mankind.

Principle of Reverse Osmosis

Reverse Osmosis system uses semi-permeable spiral wound membrane to separate and remove dissolved solids, organics, pyrogens, submicron colloidal matter and bacteria from water. Feed water is delivered under high pressure through permeators, where water permeates through the minute pores of the membrane and is delivered as purified product water.

Removal of Impurities

Impurities in the water are concentrated in the reject stream and flushed to drain.

Output Range

The system is available in a wide range of models for treating water quality of varying Total Dissolved Solids (TDS) with different flow rates.

Purity Standards Maintained

Maximum purity is attained by reducing a) 95% - 99% of the TDS

Advantages

- Hygienic drinking water for domestic use.

- Reduces the cost of de-ionized water for boiler-feed and process.

Ultra pure water for Electronic Industries

- To meet specific requirements in process industries

- Cooling Tower blow down water recovery.

- To remove fluorides from water, thus controlling fluorosis (a crippling disease).

- Conversion of brackish/sea water into potable water.

Useful for Industries such as Food, Beverages, Pharmaceutical, Micro-Electronic, Aquaculture, Hospitals, Hotels, Mineral Water etc

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Swimming Pool |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

A pool filtration plant is used to treat swimming pool water so that its chlorine and PH levels are normal. It also works to remove unsafe elements such as bacteria and algae to make the water safe for everyone to enjoy in the pool. The foremost cause of infection from water is water-borne viral, fungal, and bacterial diseases, which can create difficult health problems. These can be avoided by a modern filtration plant that takes in water from the pool for cleaning.

It is possible for solid, debris, and particulate matter to contaminate the pool, which is removed efficiently by this treatment plant. The plant will draw water from the pool continuously, remove solid suspended matter, and then destroy germs by carrying out a sterilisation process.

The Aqua Systems Technology pool filtration plant is most useful in pools that are used frequently by a large number of people, as seen in clubs and recreational centers. It helps to disinfect and clean it thoroughly, but in a fully automated way such that its operation does not require any manual supervision. The pool water temperature should be up to 40 degrees Celsius. When the filter’s pressure gauge rises to 0.5 bar above the clean operating pressure, the time has come to backwash the filtration plant.

A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.

Aqua Systems Technology is one of the best Pool Filtration Plant manufacturer, Pool Filtration Plant exporter, Pool Filtration Plant supplier in mumbai India. We are provide this Pool Filtration Plant product in all over countries. If you have this Pool Filtration Plant product please visit here or quote Now

We are one of the prominent manufacturers of Swimming Pool Filtration Plants. They are used to maintain the chlorine and PH levels of the pool to kill bacteria and algae and make the pool biologically safe. Pool water carrying particulate matter, solids and debris is passed through the filtering media that allows clear water to return to the pool. Made using mild steel, we offer various types of AST filtration plants to remove different types of dirt.

Features :

- Multiple models available

- Easy to install

- User-friendly operation

A properly maintained pool is one that is visually and biologically cleans. If the chlorine and PH levels are maintained, bacteria and algae will be killed and the pool will be biologically safe. Filtration is mechanical process of removing insoluble matter from swimming pool water. Pool water carrying particulate matter, solids and debris is passed through filtering media that allow clear water to return to the pool. Water clarity is important for appearance, hygiene and safety.

The water naturally contains dissolved and undissolved impurities. Undissolved impurities of water and precipitate sludge can be removed with the mostly popular and basic treatment of filtration. Various types of AST filtration plants are available for different type of impurities to be removed with different flow rate.

AST filters are made from mild steel/FRP closed vessel incorporating frontal piping fitted with valves and are operated under pressure. The water is passed through the filter from different grade of filter media, where unwanted impurities are left behind at the filter bed. Filter have back flushing arrangement, which very easily flushes away the deposited impurity at filter bed to cleans the filter bed, thus reverse flow of water flushes away the impurities deposited at filter bed.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

Ultrafiltration is a low-pressure membrane process used to separate bacteria, viruses, and high molecular weight compounds colloidal and particulate matters from a feed stream. Ultrafiltration has larger pores and high permeability with less osmotic effects that allows ultrafiltration to operate at relatively lower pressure than nanofiltration and reverse osmosis and is therefore it is least costly to operate.

Ultrafiltration is widely used in industry as pre-treatment for other forms of purification such as ion exchange and reverse osmosis, gelatin and protein concentration in the pharmaceutical industry, sugar clarification in the food and beverage industry, cheese and whey concentration, production of ultra pure water, clarification of juice, downstream processing, membrane bioreactors, treatment of bleach plant effluents, and recovery of lignin compounds in the pulp and paper industry. Ultrafiltration can be used to reject virus, bacteria, pyrogens, endotoxins, and particulates but not ionic species.

Hollow fiber configuration is widely used in the ultrafiltration processes. The benefit of this construction is that it allows for backwashing of the membrane when the filtrate or product flow rate has decreased due to accumulation of material on the membrane. The ultrafiltration membrane is capable of removing colloidal materials, fine suspensions, bacteria, virus, suspended material and large dissolved molecular weight organic materials.

Advantages :

- Product SDI typically less than 1

- Removal of virus, and bacteria

- Removal of microbiological matter

- Removal of colloidal matter

- Colloidal Silica Reduction

- Improvement of downstream Reverse Osmosis (RO) performance

- Consistently treated water quality irrespective of changes in feed water quality

Applications :

- Pre-treatment to RO system

- Purification of surface and well water for potable applications

- Filtration of industrial water

- Membrane Bio-Reactor

- Wastewater recycle and reuse

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Blue, Grey |

| Automatic Grade | Automatic |

| Application | Cleaning Water |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

A water softener plant is a device that is designed to remove positively charged ions of calcium and magnesium from water. It is essential to treat hard water in industries as it can cause expensive machinery and equipment to malfunction. Its polystyrene spherical resin beads, charged with sodium ions having a negative charge, will attract the positively charged calcium and magnesium ions as hard water moves through the resin beads.

As positive and negative ions get stuck with each other, hard water flows through resin beads, becoming soft, and this soft water comes out through its outlet. The Aqua Systems Technology softener plant can be in the form of an automatic, semi-automatic, or manual version.

The many different components of such a plant include the mineral tanks, brine tanks, and control wave. The filtration process occurs in the mineral tank, which holds the resin beads, while the control valve checks the amount of water that has been filtered in the mineral tank. The brine tank restores resin beads whenever they are exhausted so that they are always in a constant positive charged state, which is vital to keep the filtration process going. The resulting soft water coming out of this plant can be used for various needs ranging from factory machines to household activities.

A team of qualified and experienced TECHNICIAN is always on it�s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer�s production. Products of high quality standards.

Aqua Systems Technology is one of the best Softener Plant manufacturer, Softener Plant exporter, Softener Plant supplier in mumbai India. We are provide this Softener Plant product in all over countries. If you have this Softener Plant product please visit here or quote Now

We are one of the leading manufacturers of Softener Plants. Softening by ion exchange resin is also known as Base Exchange softening. Hard, raw water is passed through a bed of cation resin in sodium form. Ca and Mg ions, which cause hardness, are taken up by resin and in exchange sodium ions are relinquished from the resin. Raw water continues to get softened till the resin gets exhausted. We supply these plants to clients at economical prices.

Features :

- Easy to install

- Affordable

- Easy to operate

by ion exchange resin is also known as Base Exchange softening. It is the most common and probably the easiest method of removing hardness like calcium & magnesium from water and renders the water suitable for utility purpose. As the name implies ion exchange is a process in which undesirable ions are exchanged for more desirable ions.

Process :

It consists of passing raw water containing hardness through a bed of cat ion resin in sodium form. The hardness ions Ca & Mg are taken up by resin and in exchange sodium ions are relinquished from the resin. Raw water will continue to get softened till the resin gets exhausted. Bringing back the resin to its original form is called regeneration. Softener resin is regenerated by sodium chloride.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | AST |

| Body Material | FRP |

| Driven Type | Electric |

| Color | Blue |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Manual, Semi Automatic |

| Certification | CE Certified, ISO 9001:2008 |

| Voltage | 110V, 220V |

| Weight | 100-1000kg |

| Phase | SINGLE |

| Country of Origin | India |

| Type | Water Softening Plant |

| Capacity (LPH) | 0-1000 |

| Inlet Hardness(TDS) | 500 |

| Resin Volume | 50 |

| Softener Tank Type | FRP |

| Product Code | SOF-50 |

| Port | MUMBAI |

| Payment Terms | Other |

| Delivery Time | 1-2 WEEK |

| Packaging Details | INSTALLED PLANT |

WATER SOFTENING PLANT

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Industrial |

| Certification | CE Certified |

| Warranty | 1 Year |

| Country of Origin | India |

The purpose of a water treatment plant is to be used to clean up water that comes from sewage so that it can be reused. Its purpose is to reduce water pollution and the usage of fresh water. It enhances the physical, chemical, and biological quality of water from the sewage system.

Once water is used by households and various commercial and industrial sectors, it becomes dirty and is sent into sewage pipes. However, contaminants make it very dangerous for the environment, so it has to be treated with chemicals and various filtration processes. This is done by a water treatment plant, after which the cleaned up water will be reused for other purposes or sent back to the sewage network to be flushed into water bodies.

The plants will first remove physical waste solids from waste water, after which it will be treated to remove organic matter. Various chemicals will be added to bring back balance to the pH level. After suspended particles and biodegradable matter are removed, the water is cleaned up for any remnants of contaminants, after which it finally becomes clean. Some of the many industries that make use of the Aqua Systems Technology plant include metal finishing, boiler feed, food and beverage etc.

A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.

Aqua Systems Technology is one of the best Water Treatment Plant manufacturer, Water Treatment Plant exporter, Water Treatment Plant supplier in mumbai India. We are provide this Water Treatment Plant product in all over countries. If you have this Water Treatment Plant product please visit here or quote Now.

We are manufacturer of water treatment plant which consists of Sand filter + carbon filter + micron cartridge filter + ultra violet sterilizer system. This plant is very helpful where water tds is low and required only simple water purification for drinking or processing purpose.